Total Metal Recovery Solution at CARS 2018

By Paul Fears | 10 July 2018

Collect, shred, size and then separate has been the way to recover metals from auto scrap for decades and separating metals will be the focus on stand M6 at the Complete Auto Recycling (CARS) exhibition (11-12 July 2018, NAEC, Stoneleigh, Warwickshire, UK).

“Car recycling companies want to recover all the metal, with 100% purity, and lose nothing to waste,” explained Jonathan Millington, Master Magnets’ Marketing Manager. “By having a series of metal recovery stages using both Magnetic Separators [for ferrous and even weakly magnetic materials such as work hardened stainless steel] and Eddy Current Separators [for non-ferrous metals] we can recover the vast majority of large and small metal.”

Master Magnets have been manufacturing and supplying large Ferrous Scrap Drum Magnets, for primary separation of large ferrous frag, since their inception in 1978. In the 40 years since, metal separation technology has evolved with the introduction of Eddy Current Separators and ultra-strong magnetic separators, such as the Stainless Steel Separator.

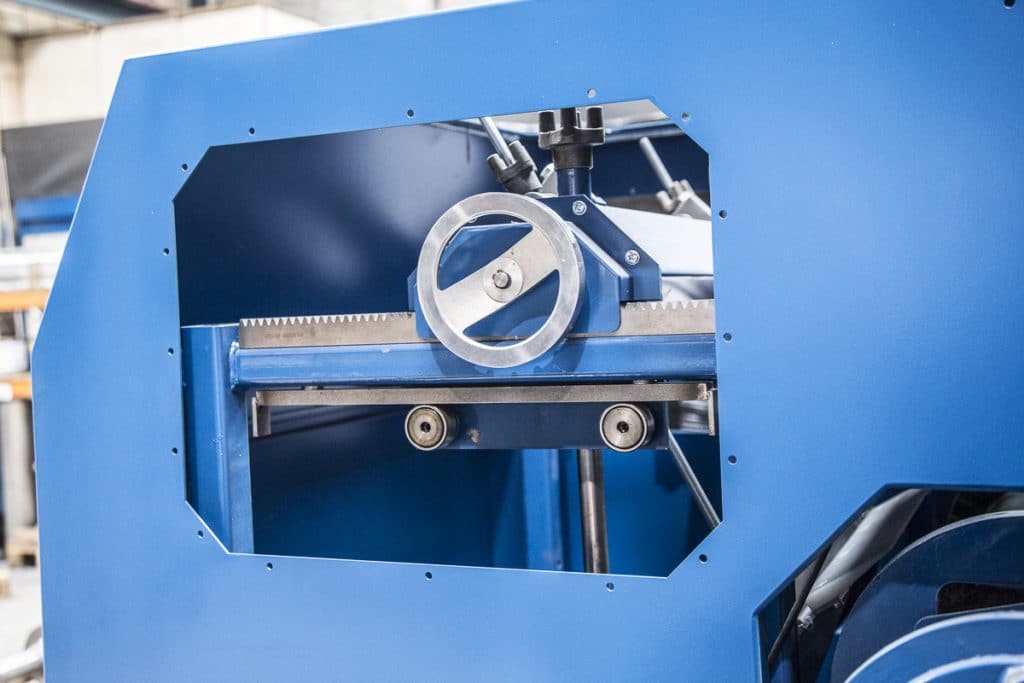

“The Eddy Current Separators you see today have been developed to separate increasingly smaller non-ferrous metals,” said Jonathan. “There are different designs of the magnetic rotor to suit specific applications, with increased magnetic strength, a variation in pole configuration, and finely tuned splitter arrangements.” A working Eddy Current Separator will be on the stand (M6) at CARS.

Also working on the stand will be a Stainless Steel Magnetic Separator. “The Stainless Steel Separator has been very successful in the USA, where it was developed by our parent company Bunting Magnetics Co” said Jonathan.

Stainless Steel Separator Customer Testimonials

“In the business of metal recycling, our profitability depends on the volume of recovered product and purity of that product. The High Intensity Separation Conveyor and its unmatched reliability to get stainless steel out of our mid-sized fraction ensures we get the purity needed to sell to our domestic smelters.” – Kevin Gershow / Gershow Recycling / Medford, New York

“I have operated a shredding facility for 8 years and I have seen many products. There isn’t anything else out there that will do what this High Intensity Separation Conveyor will do. The Bunting Magnetics group has built something that no one else in the industry has. With this HISC we are able to successfully separate Stainless Steel from our shredded wire. We estimate a payback ROI period of less than 1 year. They have been fantastic to work with. I have received excellent customer support and have been very pleased that they came to visit our facility in person. They have been very honest about the abilities of the magnet, and it has produced better results than they claimed. Currently we are removing about 300lbs (136kg) of Stainless Steel from our shredded wire daily.” – Pat Dooley / Pacific Steel & Recycling / Boise, Idaho

“The HISC has done everything that they said it would do! It has been very helpful in purifying my chopped copper wire material. I’m extremely pleased with the performance of the HISC.” – Chris Reeves / Copper State Metals / Phoenix, Arizona

Seeing Is Believing

On stand M6 at CARS, both the Stainless Steel Separator and Eddy Current Separator will be in operation. “It is important that we demonstrate what separation is possible rather than just say what it can do. People trust what they see and not what they hear,” explained Jonathan.

For additional information on Master Magnets exhibiting at CARS 18 or for any Magnetic Separator or Eddy Current Separator requirement, please contact us on:

Email: sales.redditch@buntingmagnetics.com

Telephone: +44 (0) 1527 65858