Posts Tagged ‘Mineral Processing’

High-Intensity Magnetic Separation at Ceramitec 2024

High-intensity magnetic separators reduce rejects, rework, and increase ceramic whiteness. On Bunting’s stand A6 323D at Ceramitec 2024 (9-12 April, Munich, Germany), ceramic engineers and ceramic mineral processors can find out about the latest high-intensity magnetic separation technology for both wet and dry processes. Keeping Ceramic Glazes, Slips and Bodies Free of Magnetics Fine iron…

Read MoreLaboratory WHIMS for Wardell Armstrong

Wardell Armstrong, a leading global consultancy for mining and mineral processing, has acquired a laboratory-scale Wet High Intensity Magnetic Separator (WHIMS) from Bunting. The laboratory WHIMS is for the consultancy’s material test facility located in Cornwall, United Kingdom. The laboratory-scale WHIMS is part of Bunting’s range of small-scale high-intensity magnetic separators. Wardell Armstrong is a…

Read MoreIlmenite Producer Purchases Magnetic Disc Separator

A European Ilmenite producer has purchased a 2-stage Magnetic Disc Separator (MDS). The mineral processor originally purchased their first Magnetic Disc Separator in 1995. The new magnetic separator will provide additional processing capacity as well as guaranteeing continual production. The mineral ilmenite (FeTiO3) is mined for the production of titanium dioxide, which is commonly used…

Read MoreHigh-Intensity Magnetic Separators at Ceramitec

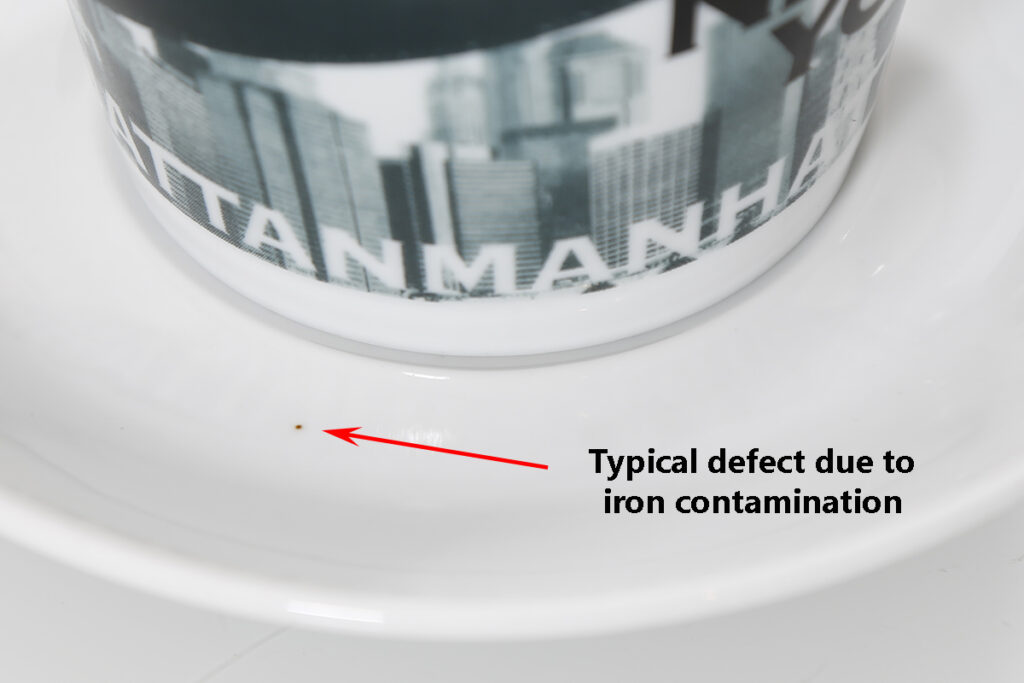

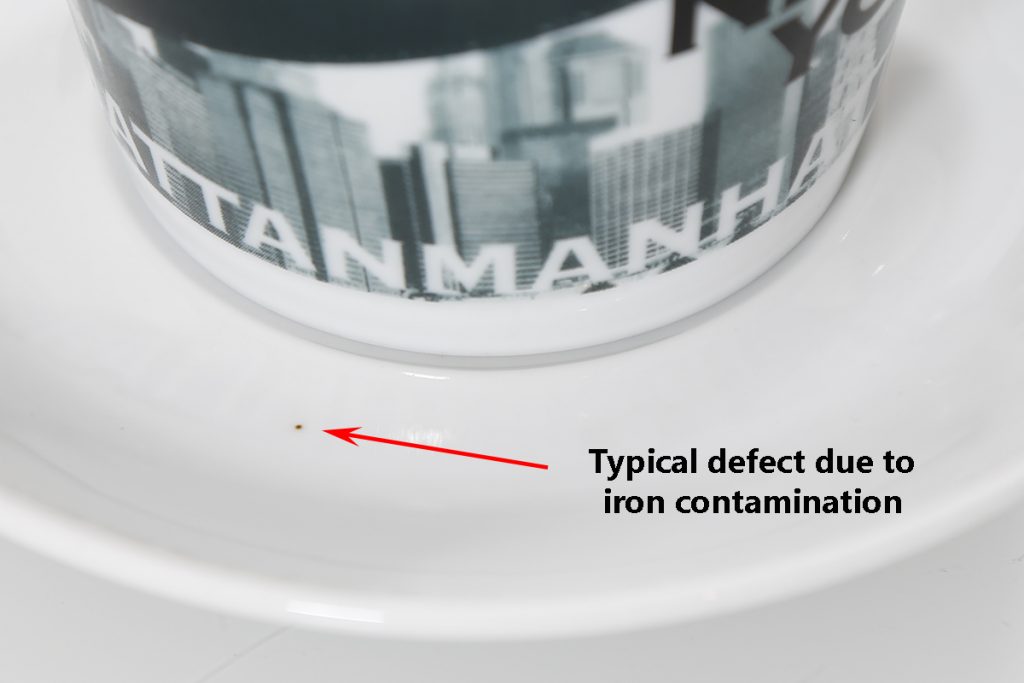

High-intensity magnetic separators play a key role in the manufacture of ceramics and the processing of ceramic raw materials, as highlighted at Ceramitec 2022 on Bunting’s stand (on stand C1:511). Keeping Ceramics Iron-Free Fine iron and magnetic minerals cause defects in any ceramic product, whether that is tableware, sanitaryware, tiles or technical ceramics. The iron…

Read MoreWire Wrapped Drum Magnet Benefits

Robust and with a high-intensity magnetic field: the Wire Wrapped Drum Magnet bridges the gap between standard Neodymium Rare Earth Drum Magnets and magnetically powerful Rare Earth Roll Magnetic Separators. Drum Magnet Technology A permanent Drum Magnet features a stationary magnetic element mounted inside a rotating non-magnetic shell. In operation, the magnetic element projects a…

Read MoreTwo Magnetic Disc Separators Process Coltan

A Nigerian mineral processor is installing two (2) Magnetic Disc Separators (MDS) to separate individual minerals in a Coltan plant. This latest export project reflects Bunting’s position as a recognised global leader for the design, manufacture, and supply of high-intensity magnetic separators for mineral processing. Technical product information: Magnetic Disc Separator Magnetic Disc Separators The…

Read MoreWet High Intensity Magnetic Separation Testing

The electromagnetic laboratory-scale Wet High Intensity Magnetic Separator (WHIMS) removes fine magnetics and para-magnetics from mineral slurries. Handling minerals in a slurry or suspension is preferable for many processors, especially when beneficiation involves wet processing. Additionally, a wet process often produces a better separation for very fine materials. In this educational video, Professor Neil Rowson…

Read MoreMagnetic Properties of Minerals

Magnetic properties of minerals

Read MoreElectroStatic Separation of Minerals

Article written by Neil Rowson, Professor of Minerals Engineering in the School of Chemical Engineering at the University of Birmingham Electrostatic phenomenon dates back to 600 – 700 B.C. when people noticed static electric effects (attraction of hair) when amber was rubbed with fur. Indeed, the word ‘electrostatic’ comes from the ancient Greek word ‘electron’…

Read MoreNew ElectroStatic Separator

The launch of the new Bunting ElectroStatic Separator is in response to enhanced material separation requirements in the recycling, plastics and minerals industries. The ElectroStatic Separator uses tungsten electrode wire to generate electrostatic charges to separate dry liberated particles. The new technology significantly broadens separation capabilities, opening up new opportunities for recovering materials from waste…

Read More