Overband Magnets

Overband magnets are suspended over conveyors to separate disruptive tramp ferrous metal, they are available as permanent and electromagnetic designs. Recent investment in manufacturing techniques and magnet technology have enabled us to offer the most comprehensive range of overband magnets with the highest levels of performance.

Supplying all industries, Bunting has the overband magnet to suit your application.

• Three distinct model types of permanent overband magnets

• Three deep field model types of electro overband magnets

• Compact and lightweight permanent and electro overband magnets

• Range of overband magnets available now from stock

Description

Description

Overband Magnets are designed to lift and automatically remove ferrous metal from conveyed material. The basic design features a permanent or electromagnetic unit mounted in a frame with two or four pulleys and a self-cleaning rubber belt.

Permanent Overband Magnet designs are commonly found on mobile equipment such as crushers, screens and shredders used in quarries and recycling operations.

Stronger Electro Overband Magnets are used on heavy duty applications as found in the Mining industry, in bulk handling terminals and also some recycling operations.

The Bunting designs have evolved over 40 years, with standard models accompanied by bespoke designs to suit specific applications.

Bunting offers:

- An extensive range of Permanent and Electro Overband Magnets to suit all applications and size requirements.

- Welding to ISO3834 accredited standards

- Accreditation to ISO9001 quality standards

- Custom design service

- Technical application engineers available to advise and assist

- Qualified service engineers and technical support

- Same day dispatch on a vast range of spare parts

Related Blogs

Operation

Material is conveyed underneath an Overband Magnet which attracts, lifts and then removes disruptive tramp ferrous metal. The size and type of magnetic system (Permanent or Electro) is dictated by the conveyor width, depth of material on the conveyor and the nature of the tramp ferrous metal.

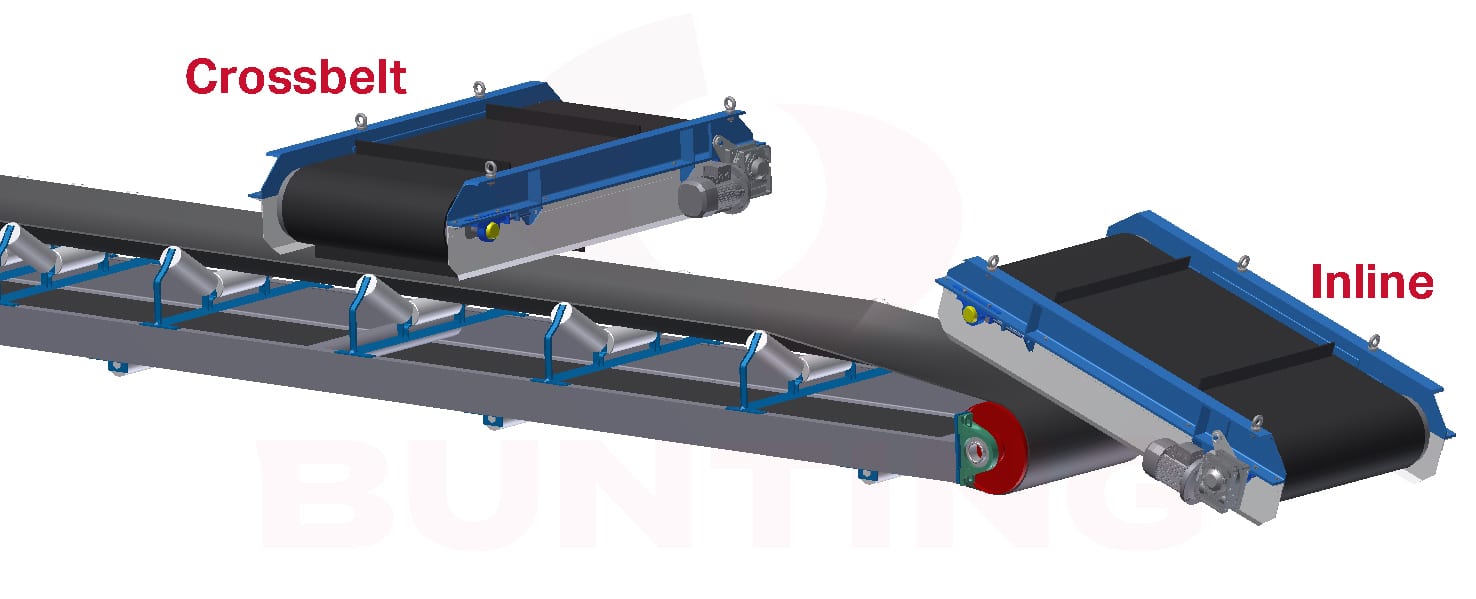

The Overband Magnets are mounted either across the conveyor belt (i.e. Crossbelt) or in line with the conveyor belt over the head pulley of the conveyor (i.e. Inline).

Permanent Overband Magnets

PCB Permanent Overband

Heavy-duty range designed mainly for recycling and quarrying industries to remove ferrous tramp. For conveyors 300 to 2000mm wide at operating heights up to 400mm

- High magnetic performance

- The selection available from stock

- Range of sizes and options to suit your application

PCB-C Compact Permanent Overband

Aimed at the mobile equipment market. More compact and lightweight. For conveyors 600 to 1500mm wide at operating heights up to 250mm.

- Latest technology resulting in reduced weight and size

- Increased magnetic force

QBC Quick Belt Change

Fast belt change overband magnet for reduced downtime. For conveyors 600 to 1500mm wide at operating heights up to 300mm.

- Top and bottom belt guides and guards

- Range of sizes and options to suit your application

Electro-Overband Magnets

High performance, lightweight, air-cooled electromagnetic overband. For conveyors 1000 to 1800mm wide at operating heights up to 600mm.

- Highest magnetic power to weight ratio of any overband magnet

- No oil present

- Low profile, compact design

- Designed using the latest finite element analysis software

OCW Heavy Duty Oil Cooled

Heavy-duty oil-cooled electromagnetic overband available for conveyors 500 to 3000mm wide at operating heights up to 1000mm.

- Manganese baseplate for high wear and impact resistance

- Unique long life powerful magnetic coil design

- ATEX rated models available

ACW Heavy Duty Air Cooled

Heavy duty air cooled electromagnetic overband available for conveyors 500 to 3000mm wide at operating heights up to 1000mm.

- No oil present

- Permanent extension magnets can be attached to extend the discharge zone away

Model Guide and Options

All our overbands have a vast range of options to suit your application and requirements.

Please call our experienced applications engineers to help specify the correct magnet and options for your individual application.

MODEL | PCB | PCB-C | QBC | EMAX | OCW | ACW |

Permanent magnet | • | • | • | |||

Electro-magnet | • | • | • | |||

Maximum operating gap (mm) | 400 | 300 | 300 | 600 | 1000 | 1000 |

Maximum customer belt width (mm) | 2000 | 1500 | 1500 | 1800 | 3000 | 3000 |

Lightweight | • | • | ||||

Air/Oil cooled electro system | Air | Oil | Air | |||

Optional Features | ||||||

Drive | Electric / Hydraulic | Electric / Hydraulic | Electric / Hydraulic | Electric | Electric | Electric |

ATEX 22 | • | • | ||||

Heat resistant, antistatic belt | • | • | • | • | • | • |

Armoured belt | • | • | • | • | ||

Stainless steel frame | • | • | • | • | • | • |

Custom design mounting brackets | • | • | • | • | • | |

Cantilever frame design | • | |||||

Full sheet guarding | • | • | • | • | ||

Belt tracking limit switches | • | • | • | • | • | |

Rotation Sensor | • | • | • | • | • | • |

Permanent magnetic extension | • | • | • | |||

Single pole magnetic system | • | • | • | |||

Twin pole magnetic system | • | |||||

Tri-polar magnetic system | • | • | • | |||

Special paint coatings | • | • | • | • | • | • |

Applications

Overband Magnets are found in most material handling plants when operating with conveyors. The correctly sized and positioned Overband Magnet will remove disruptive tramp ferrous metal to prevent damages to other processing equipment such as crushers, screens, shredders, conveyors, etc. Typical installations include:

- Mobile crushers, screens and shredders

- MRF (Material Recovery Facility) and pre-sorted refuse plants

- Municipal solid waste plants

- Quarries

- Mining Operations

- Bulk handling terminals

- Wood waste processing plants

- Fragmentiser plants for shredded vehicles

- Cullet (crushed glass) recycling plants

- Industrial skip waste recycling operations

- Foundries

Site Evaluation Service

Bunting offers a site evaluation service to gain a deeper understanding of your complex and specialised applications, this enables us to recommend the most effective solution with you on site. Please contact us on 01527 65858 to talk to one of our application engineers.