Liquid Pipeline Separators

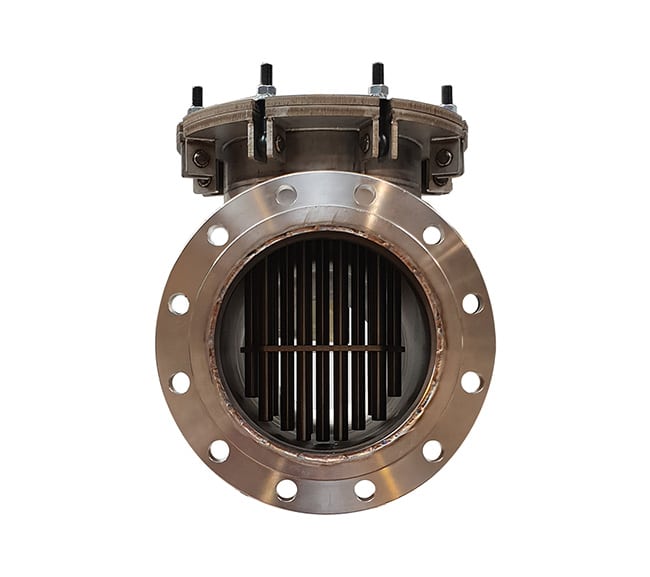

Liquid Pipeline Magnetic Separators or Traps are used for the extraction of fine iron from wet or viscous products conveyed in a pipeline. Permanent magnetic tubes, positioned in the material flow, attract and then hold magnetic metal contamination. Captured magnetic material is regularly cleaned off the magnets by removing the assembly from the body.

Description

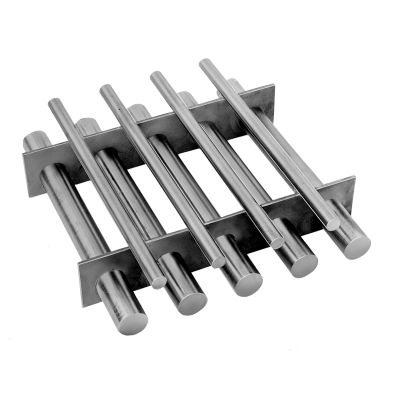

The Liquid Pipeline Magnetic Separator, also known as a Magnetic Trap, extracts fine iron and other magnetically susceptible materials from wet or viscous products conveyed in a pipeline. The magnetic tubes are available in either standard-strength Ferrite (for larger tramp metal capture) or high-strength Rare Earth Neodymium (for fine iron and abraded stainless-steel). Special Rare Earth Magnets are available when handling liquids and slurries at high temperatures. Additionally, special welds are available for corrosive applications (e.g. fruit juices).

The configuration of the Tube Magnets ensures that all the transported material passes through a magnetic field and thus ensuring the capture of magnetic particles.

The quick release mechanism on the lid of the Liquid Pipeline Magnetic Separator enables a quick and easy cleaning process to reduce downtime. The liquid pipeline separator is manufactured from stainless steel and comes complete with flanges or threaded ends. It is also available with a water jacket, for confectionery applications.

Applications

Liquid Pipeline Magnetic Separators or Magnetic Traps are used widely in the processing industry to remove metal contamination from liquids and slurries.

Typical applications:

- Food processing: Soups, Pet Food, Sauces, Tinned foodstuffs (e.g. fruit, vegetables), Fruit and Vegetable Juices, Drinks;

- Ceramics: Glaze, Slips and Body;

- Chemicals;

- Recycling: removing ferrous metal during the processing of secondary materials;

Models

Tube Magnet Style

Tube Magnets project down from the lid of the Liquid Pipeline Magnetic Separator into the material flow. The close spacing of the Tube Magnets ensures contact is made between product and the magnetic fields, maximising the separation of magnetic particles. The Tube Magnet configuration is ideal for use with non-fibrous fluids.

Available features include:

- Standard 2”, 3” & 4” Line Diameter, 1/2″ and other sizes available upon request;

- Many Liquid Pipeline Magnetic Separators are held ex-stock for immediate dispatch;

- Special heated Water-Jacket versions available for pipelines transporting material at a constant temperature (e.g. molten chocolate, hot water, etc);

Plate Magnet Style

Plate style Liquid Pipeline Magnetic Separators use either a Single or Dual Plate Magnet design. These are ideally suited for removing magnetic particles from viscous and fibrous liquids and slurries, as well as liquids containing larger suspended solids (e.g. soups, sauces and pet foods). The liquid or slurry passes close to the deep magnetic field of the Plate Magnet where metal contamination is captured, held and protected from the wiping action of the liquid flow. The incorporated deflector creates a gradual change in the direction of flow causing agitation of the product and exposes contaminants that would otherwise be blocked by suspended solids.

Available features include:

- 400 Stainless steel tapered live step is standard. 316 Stainless steel is available;

- Available with food grade and sanitary finishes;

- Standard 1″ – 4″ inlet with 1/2″ sizes available, and special sizes upon request