Suspension Magnets

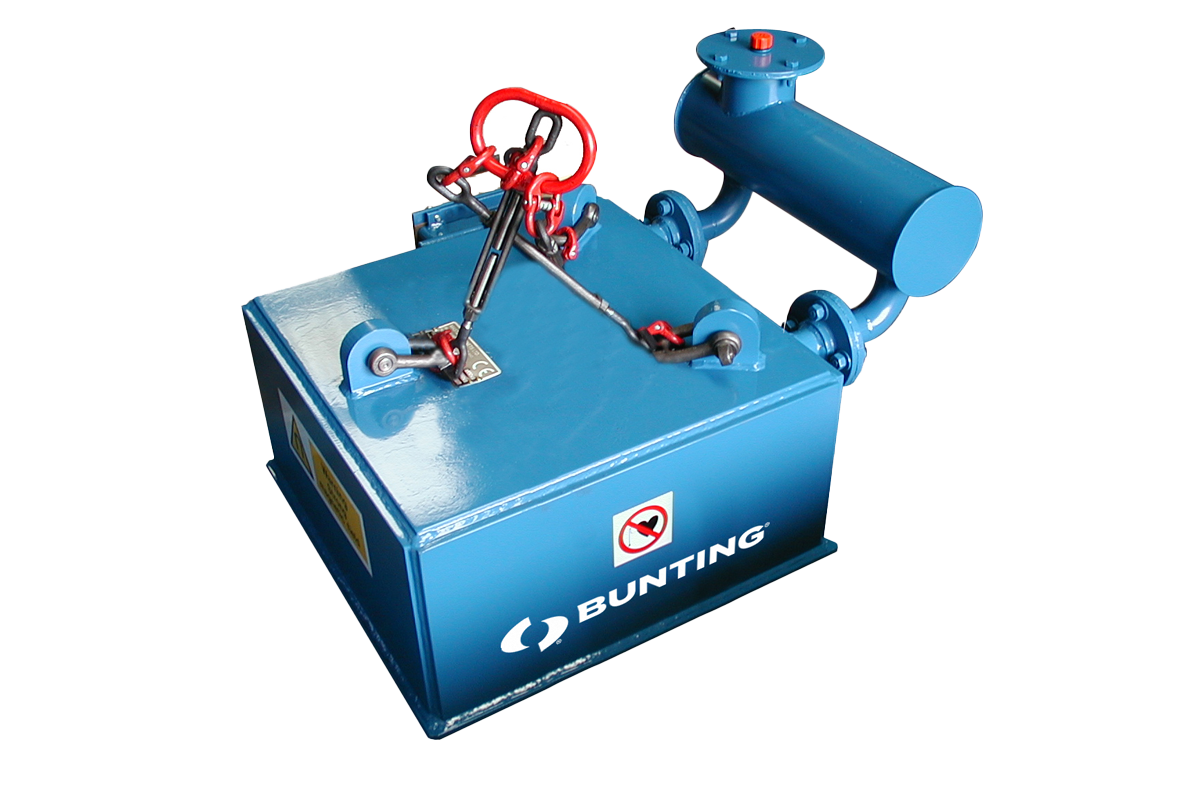

Suspension Magnets sit above conveyors to separate tramp ferrous metal and are available in permanent and electromagnetic versions.

The range of Bunting Suspension Magnets continually expands to cater for the ever-increasing size of conveyors, deeper troughs, and higher conveyor speeds. The wide range of magnet configurations ensures that there is a Suspension Magnet model to suit every application. There are two types of Suspension Magnet:

- Permanent Suspension Magnet (bi-polar and tri-polar designs)

- Electro Suspension Magnet

Description

Suspension Magnets extract occasional tramp iron from a conveyed product stream on a conveyor belt or vibratory feeder. The Magnet block suspends above a conveyor with sling chains setting the magnet face at the correct angle for optimum extraction. The magnetic field attracts ferrous metal out of the conveyed material and onto the magnet face, remaining securely held until manually cleaned. This ensures that such tramp metal does not damage other processing plant such as crushers, screens, and conveyors.

For cleaning, re-positioning the Electro Suspension Magnet away from the conveyor allows for safe discharge into a secure collection area when the magnet is de-energised. A Permanent Suspension Magnet suspended on a travelling trolley, allows easy movement away from the conveyor for manual cleaning.

Related Blogs

Operation

In operation, conveyed material passes underneath a Suspension Magnet, which attracts and lifts the tramp metal. The size and magnet type (Permanent or Electro) is determined by the conveyor width, depth of material on the conveyor and the nature of the tramp ferrous metal.

The Suspension Magnet is mounted either across the conveyor belt (i.e. Crossbelt) or in line with the conveyor belt over the head pulley of the conveyor (i.e. Inline).

Installation Options

Whilst the most common mounting position for a Suspension Magnet is crossbelt, inline models maximise magnet efficiency due to the material already being airborne and splayed.

Simplified Cleaning Options

Geared Trolley: Enables simple movement of the Suspension Magnet aside from the conveyor for the manual removal of ferrous materials.

Rubber Stripper Sheet: A heavy-duty rubber belt is fitted to one end of the Suspension Magnet and is wrapped around the working face and attached, under tension, to a pulley on the other end of the magnet. Accumulated tramp iron is easily removed from the working face by simply drawing the belt back underneath the magnet.

Steel Stripper Tray: A stainless-steel stripper tray, with catchment lip, is fitted beneath the magnet on slide rails. The tray is pulled along the rails and the captured ferrous metal is moved, by the catchment lip, out of the magnetic field and away from the conveyor for collection.

Models

Suspension Magnets are ideally suited to separate ferrous metal from conveyors with widths between 450mm and 2000mm. For belt widths less than 450mm, Bunting would recommend a Plate Magnet as a more cost-effective solution.

Electro Suspension Magnets produce a deeper field and suit applications where there is a burden depth of material on the conveyor or there is a need to operate with an increased working gap (distance between the conveyor and the magnet face).

Bi-Polar and Tri-Polar Designs of Permanent Suspension Magnet

Bi-Polar – The Bi-Polar configuration is the most common design of Permanent Suspension Magnet. The optimised shape and gradient of the magnetic field is ideally suited for separating larger tramp ferrous metal.

Tri-Polar – For applications requiring the extraction of small ferrous contaminants such as nails and screws, the optimum design is the Tri-Polar Permanent Suspension Magnet. The Tri-Polar Suspension Magnet has a core, magnetic poles and back bar in high permeability mild steel. The Tri-Polar design reduces the leakage of magnetic flux leakage with the magnetic field focused directly onto the centre of the conveyor belt to maximise ferrous metal extraction.

Air and Oil Cooled Electro Suspension Magnets

Oil cooled – The most common heavy-duty Electro Suspension Magnet with the ability to efficiently maintain an optimum working temperature and, thus, a stable strong magnetic field. Oil cooled designs produce a higher magnetic force than the equivalent air cooled electromagnets.

Air cooled – Ideally suited for applications where oil is classified as a potential hazard (e.g. explosive environments).

Applications

Most bulk handling plants using conveyors feature Suspension Magnets or Overband Magnets. Typical installations include:

- Mobile crushers, screens and shredders

- MRF (Material Recovery Facility) and pre-sorted refuse plants

- Municipal solid waste plants

- Quarries

- Mining operations

- Bulk handling terminals

- Plastic waste recycling

- Wood waste processing plants

- Car Shredding Plant

- Cullet (crushed glass) recycling plants

- Industrial skip waste recycling operations

- Foundries

Videos