News

Overband Magnet Extended by 56%

A challenging installation on mobile recycling plant led to Bunting designing and building a Permanent Overband Magnet with a magnet block over 56% longer than normal. The model PIL Overband Magnet was extended from the standard length of 1100mm to 1725mm. Permanent Overband Magnets are suspended over conveyor belts transporting material to separate ferrous metals,…

Read More120 ElectroMax Overbands Sold in Five Years

April 2024 marks five years since the launch of the ElectroMax Overband Magnet and, in that period, Bunting has built and shipped 120 units for a value exceeding £3 million. The ElectroMax Overband Magnets provide the enhanced separation of ferrous metal from conveyed material in recycling plants, mines, and quarries, bulk handling terminals, and power…

Read MoreBoosted Metal Separation with ElectroMax-Plus Overbands at W Maw

General skip waste recycler W Maw Recycling Ltd has installed two Bunting ElectroMax-Plus Overband Magnets at their Rotherham operation in the United Kingdom. The powerful electromagnetic ElectroMax-Plus Overbands replaced permanent overband magnets to separate larger and heavier ferrous metal that could damage shredders and other process plant. Replacing Permanent Overband Magnets with the ElectroMax W…

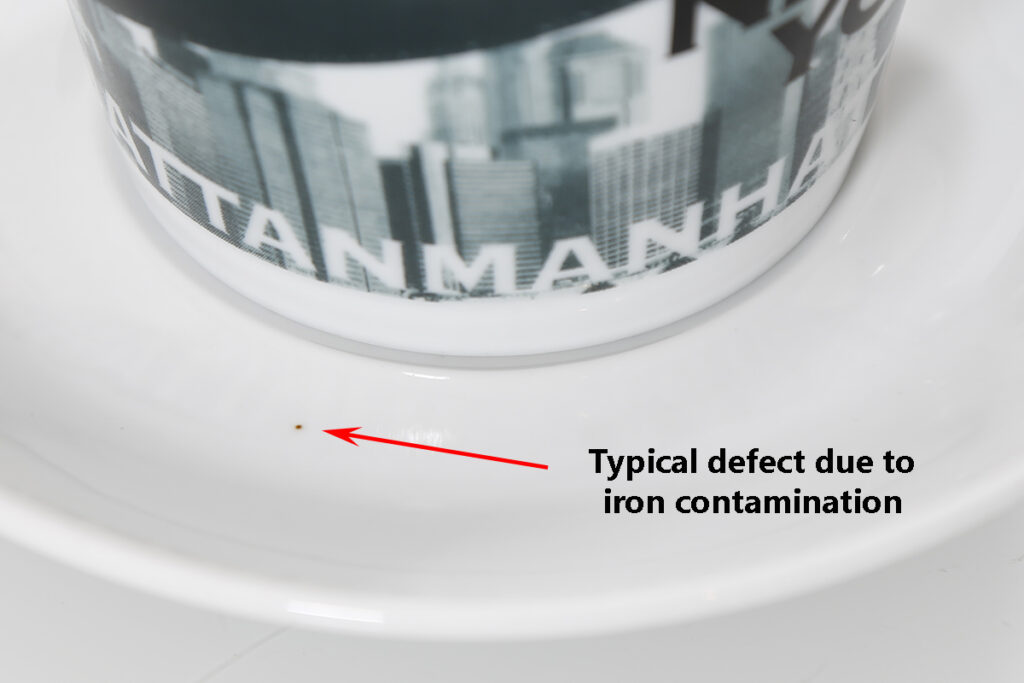

Read MoreHigh-Intensity Magnetic Separation at Ceramitec 2024

High-intensity magnetic separators reduce rejects, rework, and increase ceramic whiteness. On Bunting’s stand A6 323D at Ceramitec 2024 (9-12 April, Munich, Germany), ceramic engineers and ceramic mineral processors can find out about the latest high-intensity magnetic separation technology for both wet and dry processes. Keeping Ceramic Glazes, Slips and Bodies Free of Magnetics Fine iron…

Read MoreTowable Electro Magnetic Sweeper for Indonesian Airport

Bunting has designed and built three (3) large Towable Electro Magnetic Sweepers (model EMRS24) for cleaning an Indonesian airport runway of ferrous metal detritus. The Towable Electro Magnetic Sweeper is designed to clear ferrous debris from airport runways, roads, at shipping ports, large car parks, and large warehouses or manufacturing plants. The magnetic force is…

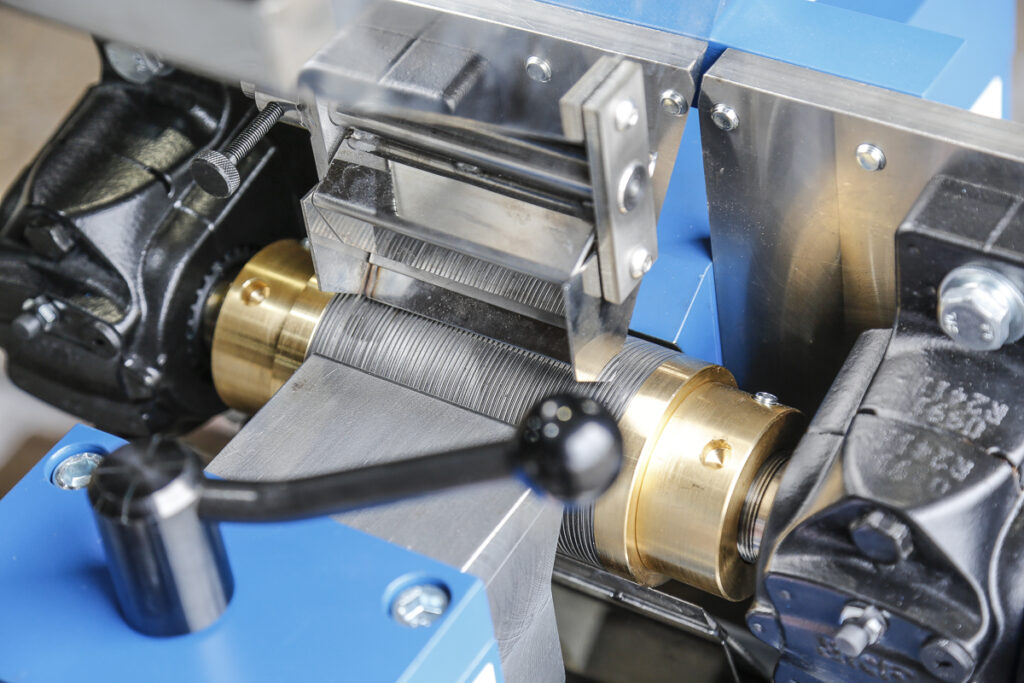

Read MoreIndustrial Magnetiser Investment for Bunting

To meet the increased demand for magnetic separators following a sustained period of sales growth, Bunting has redesigned and refurbished the industrial magnetiser at their Redditch manufacturing facility in the United Kingdom. The enhancements make this DC impulse industrial magnetiser the largest in the UK, outside of academia. Magnetising Permanent Magnet Assemblies At the Redditch…

Read MoreEnhanced Metal Recovery with Bunting at IFAT 2024

Technology to effectively separate large and small ferrous and non-ferrous metal is the focus for Bunting at IFAT Munich 2024 (Messe Munchen, Germany, May 13-17). Advanced designs of magnetic separators, eddy current separators and electrostatic separators separate strongly and weakly magnetic particles, enabling the successful recycling of a wide range of waste materials. On stand…

Read MoreMBA Polymers Install Quick Clean Drawer Magnet

MBA Polymers has installed a new quick manual-clean magnet insert into one of their existing Drawer Filter Magnets installed at their Worksop plastics recycling operation in the United Kingdom. The new insert significantly reduces the time needed to clean captured ferrous metal off the high-strength tube magnets, whilst also proving easier and safer for operators.…

Read MoreLaboratory High-Intensity Magnetic Separator for Battery Recycling Research

A European mining and technology university has purchased a laboratory-scale Bench Induced Roll Magnetic Separator (BIRS) for use in research projects including the recycling of lithium-ion batteries. The BIRS generates high-intensity magnetic fields up to 2 Tesla (20,000 Gauss), enabling the separation of weakly magnetic particles. The Induced Roll Magnetic Separator (IRS) The Induced Roll…

Read MorePermanent Overband Magnet Selection Criteria

Permanent Overband Magnets are commonplace in most mines and quarries, removing tramp ferrous metal and protecting crushers, screens and conveyors against damage. Overband Magnets are also widely used in recycling, recovering ferrous metals and protecting shredders against metal damage. However, there are many different designs of Permanent Overband Magnet, developed to suit specific applications. Understanding…

Read More