Aggregate and Quarrying

Removing Metal Contamination from Aggregate & Quarries

- Quarry and aggregate Metal Detectors are commonly used alone or alongside magnetic separators to detect all tramp metal including digger teeth (manganese steel);

- An Overband or Suspension Magnet sit across or over conveyors to lift and separate ferrous tramp;

- A Pulley Magnet replaces a conveyor head pulley and automatically attracts and separates ferrous tramp metal from the conveyed aggregate or quarried rock;

Technical Articles

- American Quarries Install TN77 Metal Detectors

- Junction City Mining Installs Overband Magnet in US Quarry

Aggregate and Quarrying Industry Products

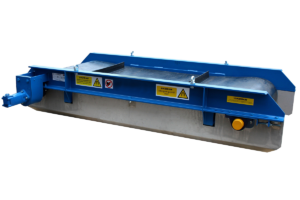

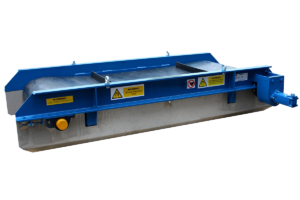

Overband Magnet

Suspension Magnet

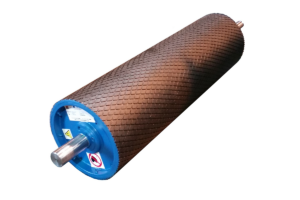

Magnetic Head Pulleys

TN77 Metal Detectors

Aggregate and Quarrying Industry Products

Overband Magnets

Overband magnets are suspended over conveyors to separate frequently-occuring disruptive tramp ferrous metal and are available as permanent and electromagnetic designs.

Suspension Magnets

Suspension Magnets sit above conveyors to separate occasional tramp ferrous metal and are available in permanent and electromagnetic versions. The captured metal is held securely on the face of the Suspension Magnet until manually cleaned.

Magnetic Head Pulleys

The Magnetic Head Pulley replaces the standard head pulley of a conveyor to provide continuous separation of disruptive tramp ferrous metal from a conveyed product.

TN77 Metal Detectors

The TN77 Industrial Metal Detector detects damaging tramp metal present in conveyed materials such as aggregates, mined ore, and recycled materials. This includes identifying both tramp iron and manganese steel (e.g. digger teeth).

Metal Detectors for Aggregates and Quarries

Aggregates and quarry metal detectors identify tramp metal that causes costly damage to screens, crushers, and conveyors. Once identified, the tramp metal is either manually or automatically removed, ensuring that production is unaffected. Bunting’s range of aggregate and quarry metal detectors are installed in operations across the world.

Magnetic Separators for Aggregates and Quarries

Magnetic Separators for the aggregates and quarry industry separate tramp ferrous metal and commonly work in conjunction with a metal detector. Removing ferrous metal reduces to amount of metal passing through the metal detector and, especially for manual metal removal, significantly reduces production downtime. Bunting’s range of permanent and electro magnetic Overband Magnets and Suspension Magnets are world-leading.